Make machining programs by inputting cross sectional shapes such as straight lines, tapers, and arcs. High precision 5-axes simultaneous machining of complex contours at high speed feedrates (MAZATROL SmoothX). MAZATROL Smooth graphical user interface for unsurpassed ease of operation. Touch screen operation - Operates similar to your smartphone / tablet. Smooth Process Support Software can integrate your machines and processes for higher productivityĭisplay varies by machine specifications MAZATROL SmoothX, MAZATROL SmoothG Latest hardware and software for unprecedented speed and precision Smooth Technology ensures higher productivity

Make machining programs by inputting cross sectional shapes such as straight lines, tapers, and arcs. High precision 5-axes simultaneous machining of complex contours at high speed feedrates (MAZATROL SmoothX). MAZATROL Smooth graphical user interface for unsurpassed ease of operation. Touch screen operation - Operates similar to your smartphone / tablet. Smooth Process Support Software can integrate your machines and processes for higher productivityĭisplay varies by machine specifications MAZATROL SmoothX, MAZATROL SmoothG Latest hardware and software for unprecedented speed and precision Smooth Technology ensures higher productivity

MAZATROL Smooth CNC series with advanced Smooth Technology - Designed to increase your productivity

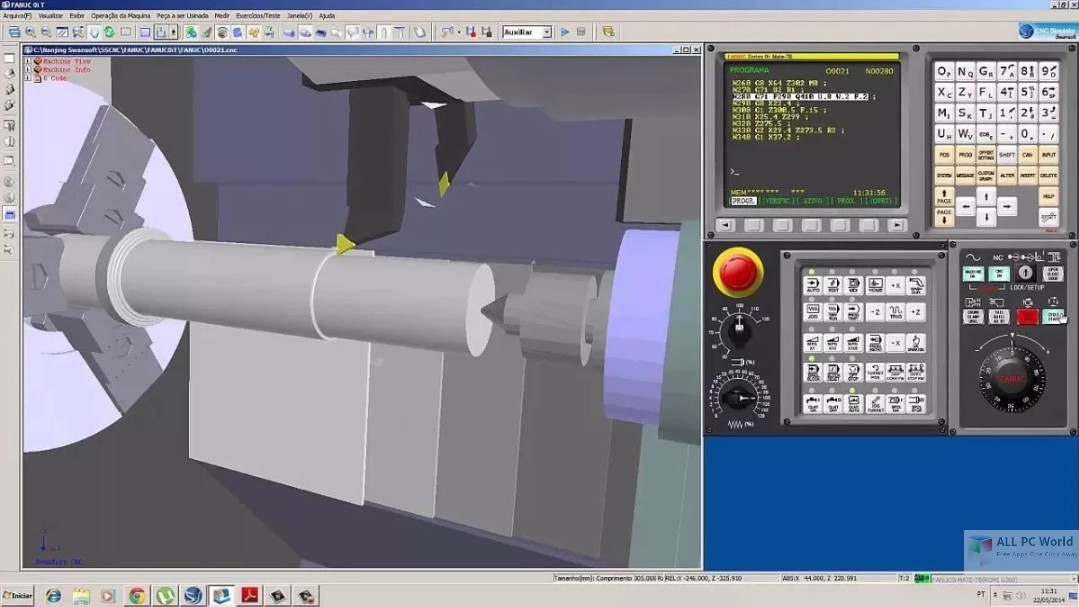

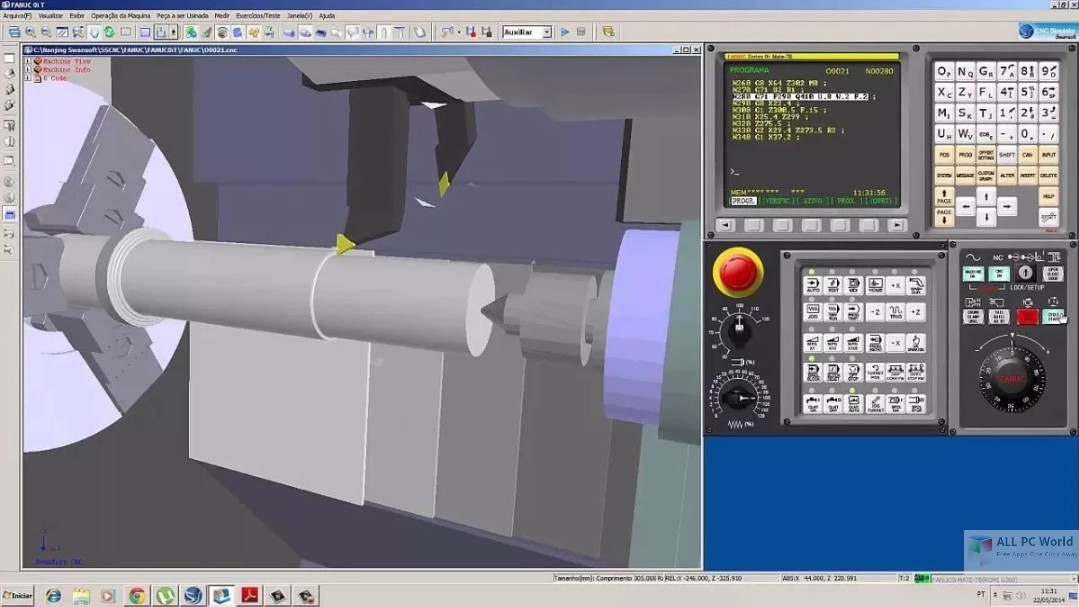

Font size can be changed bigger or smaller for ease of operation. Operators can easily create the programming by checking shapes and processes. Thanks to display the 3D workpiece model on the screen,. Programs can be easily created and checked by utilizing the touch screen and displaying the 3D workpiece model. QUICK MAZATROL makes it possible to reduce the programming time.

Flexible Layoutĭisplay data, menu and screen keyboard position can be changed in the CNC screen.ĭata can be checked and set with minimum screen transitionīy customizing the display according to operation process. The control is responsive, efficient and easy to learn, even for new operators. Intuitive operation with 15" touch screen High-speed high-accuracy machining with new functionsĮfficient operation with software integration Three "E z (easy)" features for higher productivity For further details, please contact your nearest Mazak office. Additional purchases may be necessary depending on the customer environment. The user is required to prepare the touch probe and reference sphere for on machine measurement. Easy creation of measurement programs by conversational programming.Elimination of variances in manual measurement results (vernier caliper„micrometer„bore gauge, etc.).

This system reduces set-up time and helps prevent defects

The operator does not need to load and unload the workpieces to measure it each time. Improving of production lead time and prevention of defective products On-Machine Measurement Software for improving of production lead time On-Machine Measurement Software Measurement of a workpiece on the machine New algorithms automatically determine the amount of compensation to be automatically applied according to changes in the temperature to ensure even higher machining accuracy. Thanks to AI learning, which utilizes machining expertise from accumulated programming experience, the optimum machining processes will be automatically determined and programs will be generated.Įnsures stable machining accuracy Ai Thermal Shield ensures enhanced heat displacement compensation Optimum machining process thanks to AI learning

0 kommentar(er)

0 kommentar(er)